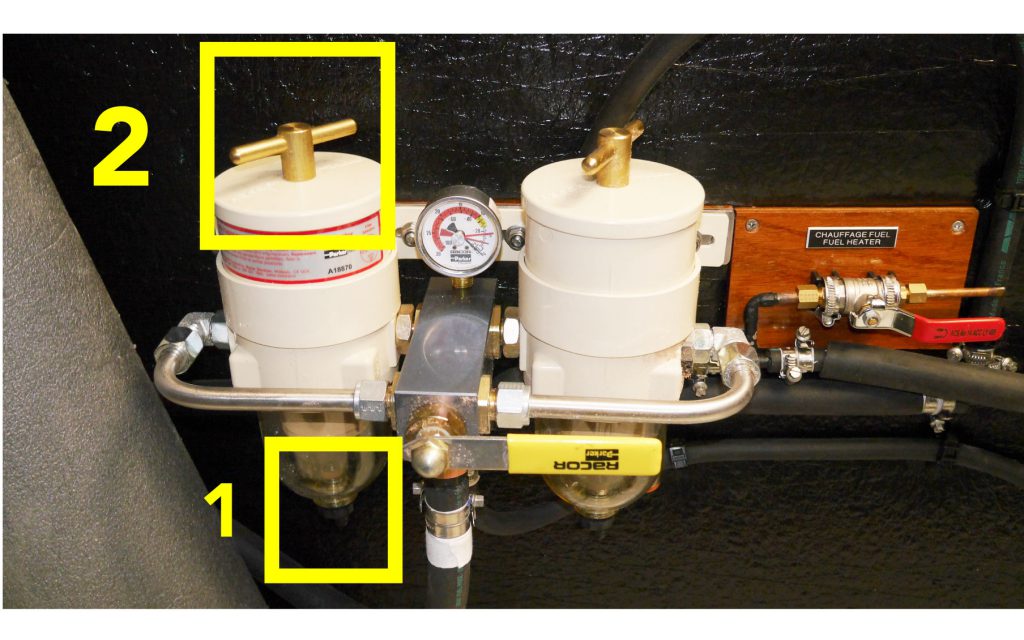

Diesel separator pre-filters

Separator pre-filters filter diesel coming from a tank before it is distributed to the various parts (engine, electrical generator set, heating system). It filters impurities and separates water and fuel, if necessary. Our boats are equipped with 2 filters, which means that there will always be a clean filter available if the first one gets clogged. Like all filters it must be replaced regularly. A filter is expected to provide 500 hours of use. Given that it filters diesel for several different parts it is necessary to add up the operating times of the various parts to evaluate the remaining filter service life.

It is generally recommended, if possible, to only use one filter at a time. This filter is then changed and the second one is used during the second period in order to always to have a clean, new filter available.

An initial visual check allows the state of the pre-filter to be assessed: presence of water, colour, presence of deposits at the bottom of the separator, etc.

Equipment required :

Tools :

- A can for recovering the used diesel

- An oil syringe (Jabsco hand pump) for emptying with various tubes

- Plastic bags to use during the removal of the filters

- Cloths

- Portable 24V lamp or equivalent

- Toolbox with Allen keys + ratchet set in inches

- Bucket with large rubbish bags

- Solvent cleaner

Supplies :

- 1 RACOR 10 micron filter kit

Procedure :

Proceed accordingly:

- Ensure that the valve of the separators is in the closed position (arrow upwards).

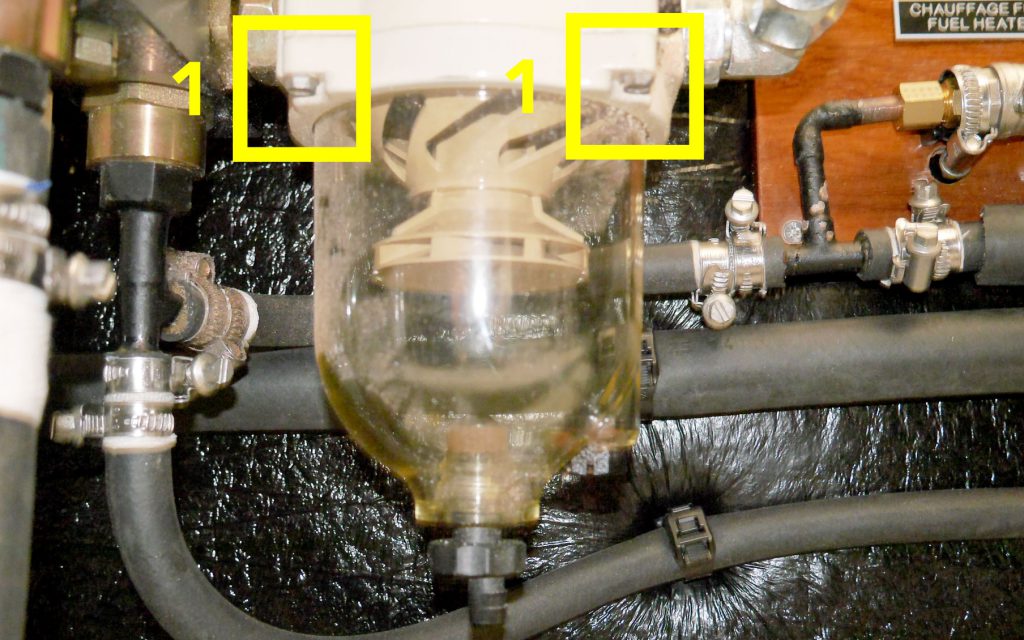

- Drain the lower part of the separator by unscrewing the drain screw (fig. 1).

- Open the butterfly valve on the top of the separator (fig. 2)

- Pump the diesel using the hand pump.

- Replace the filter cartridge making sure to also replace the gaskets.

- The lower part of the separator may also require cleaning:

- Loosen the 4 screws retaining the bowl flange (fig. 1). Be careful with the heads of the screws which are fragile. Tools: small ratchet / long extension and socket in inches

- To fill the separator with diesel (1L) ensure that the separators’ multi-way valve is closed and that the top cover of the separator is open. Then open the diesel valve in the alleyway and return to the engine room. Open the separator valve on the correct side and monitor that it is filling correctly. Filling happens in two phases so that the filter is completely soaked through. Once the separator is full to the brim, reposition the cover with the gasket and screw it on by hand.

- During start-up: start with the new filter in order to remove any air bubbles that may have occurred, then switch-over to the old filter for several minutes. The latter must then be used until the next service to ensure that there is always a clean, new and recent (less than one year old) ready to use.